Custom Linear Actuator - Bruin Racing Baja SAE

What?

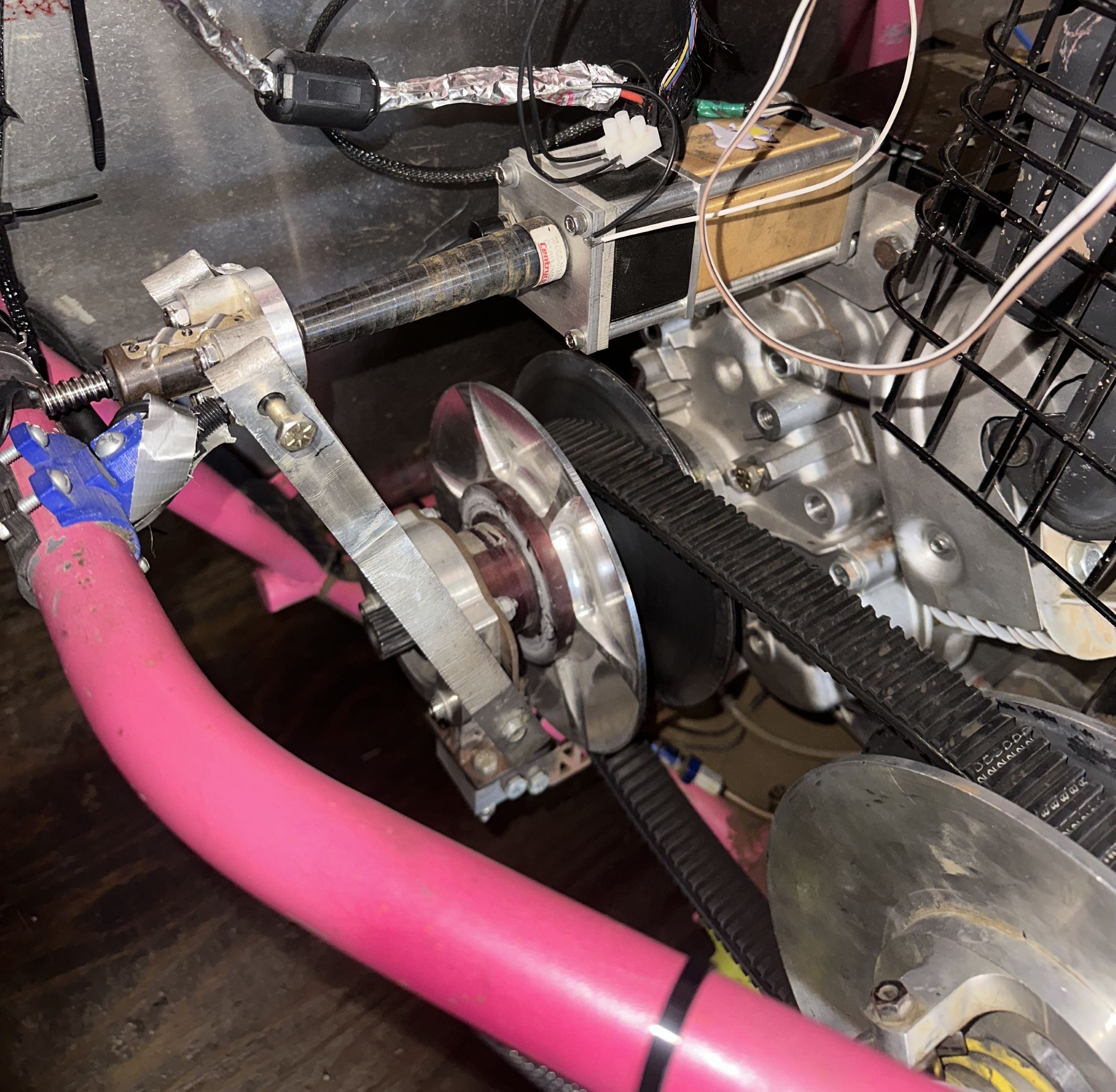

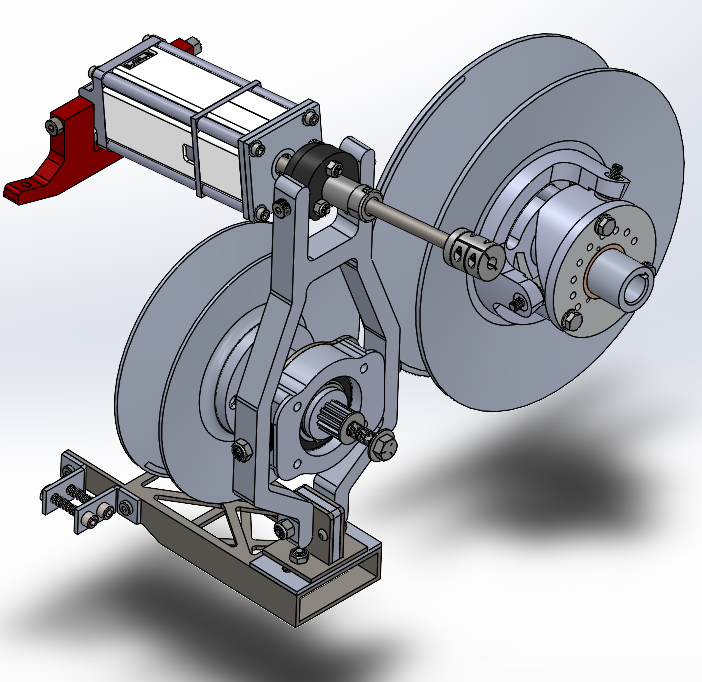

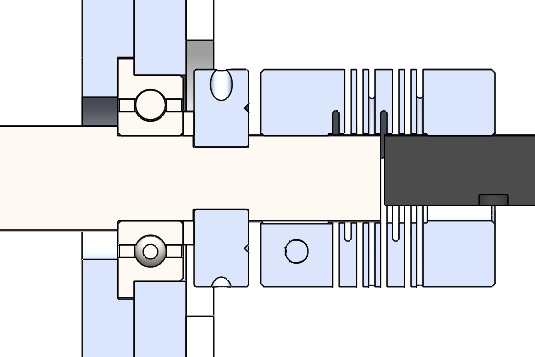

With benefits in tunability and the ability to change shift profiles on the fly, Baja SAE at UCLA is one of the only teams in the U.S. that uses an electronically-controlled continuously variable transmission (ECVT). I was responsible for the design of a custom ball-screw linear actuator used to shift belt ratios in the 2020-2021 Baja vehicle.

The initial version of UCLA's ECVT two years prior used the Thomson MaxJac, an off-the-shelf linear actuator. However, the COTS actuator's insufficient shift-out speed led to frequent stalling. While the previous year's custom linear actuator had much-improved shift speed, the coupling between the motor shaft and ball screw failed. As a result, I aimed to maintain sufficient shift speed while prioritizing robustness in my acutator design.

How?

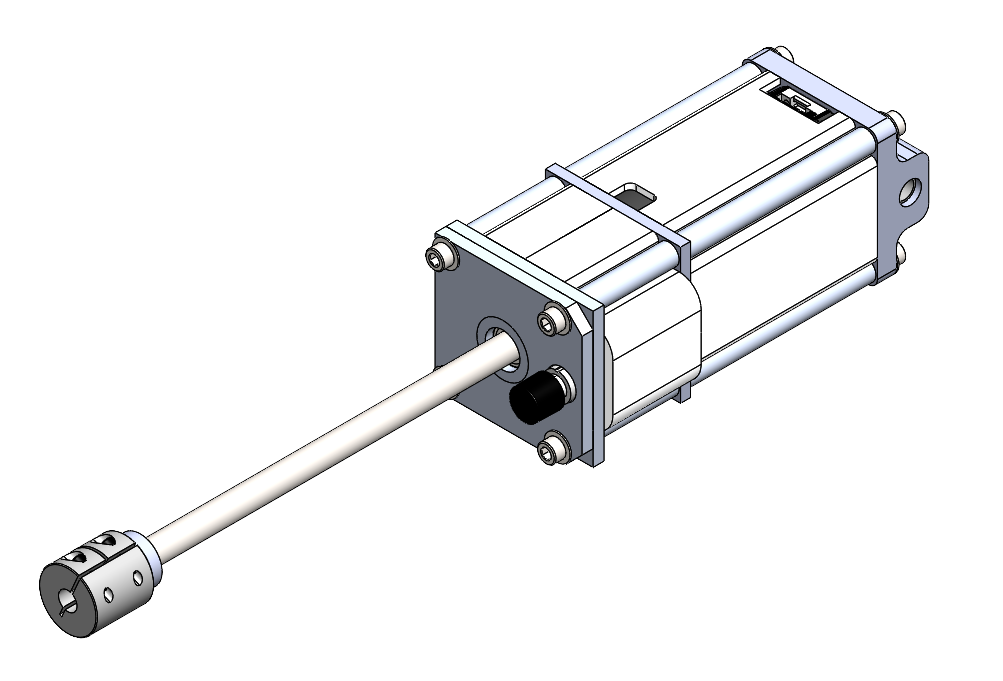

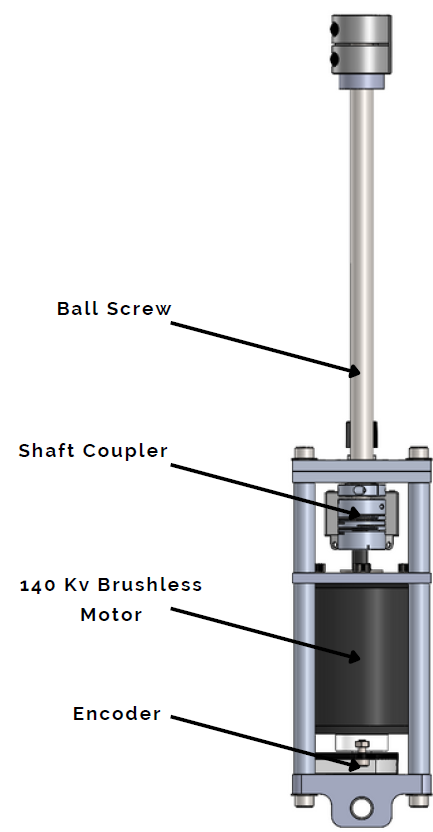

My revised actuator design prevented the shaft coupler from seeing any tensile load (which had pulled the ball screw out from the coupler previously) or any compressive load (which could damage the electric actuator motor).

Additionally, I eliminated the old actuator's potentiometer used to measure shift position in favor of a rotary encoder, increasing reliability and improving ease of integration with the ODrive motor controller.

Results

While not manufactured in 2021 due to COVID, the actuator was manufactured as designed and used in 2022 competition. A 2.8x increase in shift speed over the Max Jac prevented stalling, and the actuator experienced no mechanical failures.